Technologies

Sustainable by Nature. Innovative by Design.

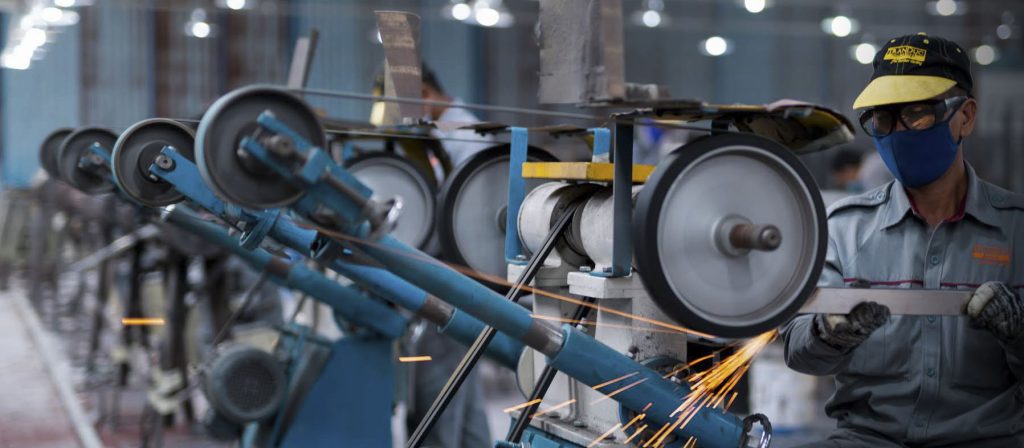

Production Capability

We own two modern home frame manufacturing lines: wooden and Light Gauge Steel structures. With more than 20 years of experience in wood manufacturing, we can provide the best quality of houses, from structure to furnishings.

A modern production line allows the modules to be manufactured and completed in the factory with optimal efficiency, then transported to the construction site for installation, reducing construction time. Thus, Modulux Homes can manufacture modules from 4-7 days and construct the house within 3-5 days.

Modern Production Line

Components

Components go through processing steps to meet quality standards suitable for architectural interior and exterior finishing, offering a variety of color options and surface finishes to match different design styles and personal preferences.

Furnishings

With over 20 years of experience in providing high-end hospitality furnishings, we are confident in our ability to understand customer needs and our capacity for A to Z production. Our products are a reliable choice for those seeking a luxurious living space that is both elegant and sophisticated.

Panelized Installation

Panels are pre-installed onto the structure at our factory forming modules (includes structural framework). Upon arrival at the installation site, modules are assembled together on a fixed foundation culminating in the construction of a fully assembled house

Modular Installation

Panels are manufactured at our factory then transported to the installation site. Upon arrival, the structural framework is deployed atop a foundation, followed by the individual installation of panels, culminating in the construction of a fully assembled house.

Framework

Steel frame: made from light gauge steel through the fully automated FRAMER X5 system with various dimensions ranging from 89mm to 250mm, providing increased flexibility to cater to the specific requirements of each project. Wood frame: employing global-standard wood treatment technologies, the wood frame is capable of meeting all the demands of architectural construction projects.